Brands like Hi-Seas Products provide kits containing various crimp sleeves and chafe gear, allowing you to create your own leaders using heavy monofilament or fluorocarbon lines. Jim Hendricks

As the thickness of leader material increases, using knots to connect hooks, swivels, and lures, as well as forming loops for snaps, becomes less effective. Typically from around 80-pound-test upwards (whether monofilament or fluorocarbon leader), knots can be difficult to tighten properly, become overly bulky, and may come undone. Crimps offer a reliable and sleek connection.

Similar to knots, crimps are essential connections to fish, so employing the right crimp sleeves, tools, and techniques is crucial. To gain insights, we consulted Capt. Shawn Rotello, owner and operator of Night Runner sportfishing charters based in Kona, Hawaii. Rotello targets blue marlin, yellowfin tuna, wahoo, and ulua (giant trevally) in the leeward areas of the Big Island. Here are his recommendations on crafting effective crimps using a hand crimper.

Select the Correct Sleeve Size

Correct Diameter

Jim Hendricks

Begin by ensuring that the crimp sleeve is appropriately sized for the line, according to Rotello. “If the sleeve is too small, the line won’t fit inside; if it’s oversized, the sleeve may fail to crimp tightly enough to prevent the line from slipping,” he clarifies. Hi-Seas simplifies this by marking packaging for crimp sleeves according to specific pound-test ratings. You can also align the diameter of the sleeve with that of the leader, which should be indicated on the packaging of both the sleeves and the leader material.

Aluminum vs. Copper Sleeves

Aluminum vs. Copper

Jim Hendricks

Crimp sleeves for both monofilament and fluorocarbon are available in two varieties: oval aluminum and double-barrel copper. Anglers often debate which one is superior, yet Rotello offers the following insight: “I generally prefer double-barrel copper sleeves for leaders weighing 130-pound-test and lower, as they tend to be gentler on lighter lines.” For leaders that are 150-pound-test and above, he opts for aluminum sleeves. Larger leaders correlate with proportionately larger sleeves, while the lighter aluminum material aids in reducing weight for improved lure and live-bait performance.

Sleeve Length

Sleeve Length

Jim Hendricks

Crimping sleeves are available in two lengths: short and long. Short sleeves are preferable for lighter leaders or fishing for line-shy species. Long sleeves fit heavier leaders better and are more appropriate for situations where the crimp will not be visible, such as within the skirt of a trolling lure or inside a rigged bait.

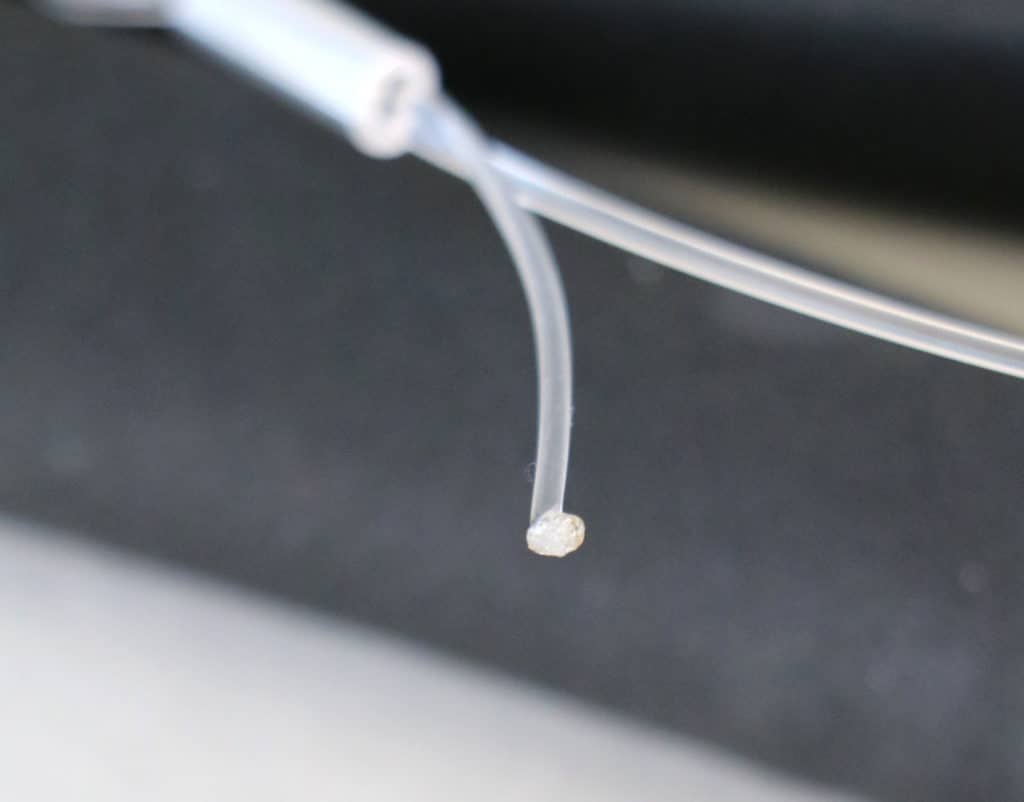

Melt the Tag End

Melt the Tag End

Jim Hendricks

Rotello suggests this step prior to crimping: After threading the leader through one side of the sleeve and back through the opposite side, pull out about 3 to 4 inches of the tag line. “Melt the tip of the tag line using a lighter,” he advises. “This creates a small blob of material at the end that prevents it from slipping out of the crimp.” After it cools, align the end of the tag with the crimp’s end.

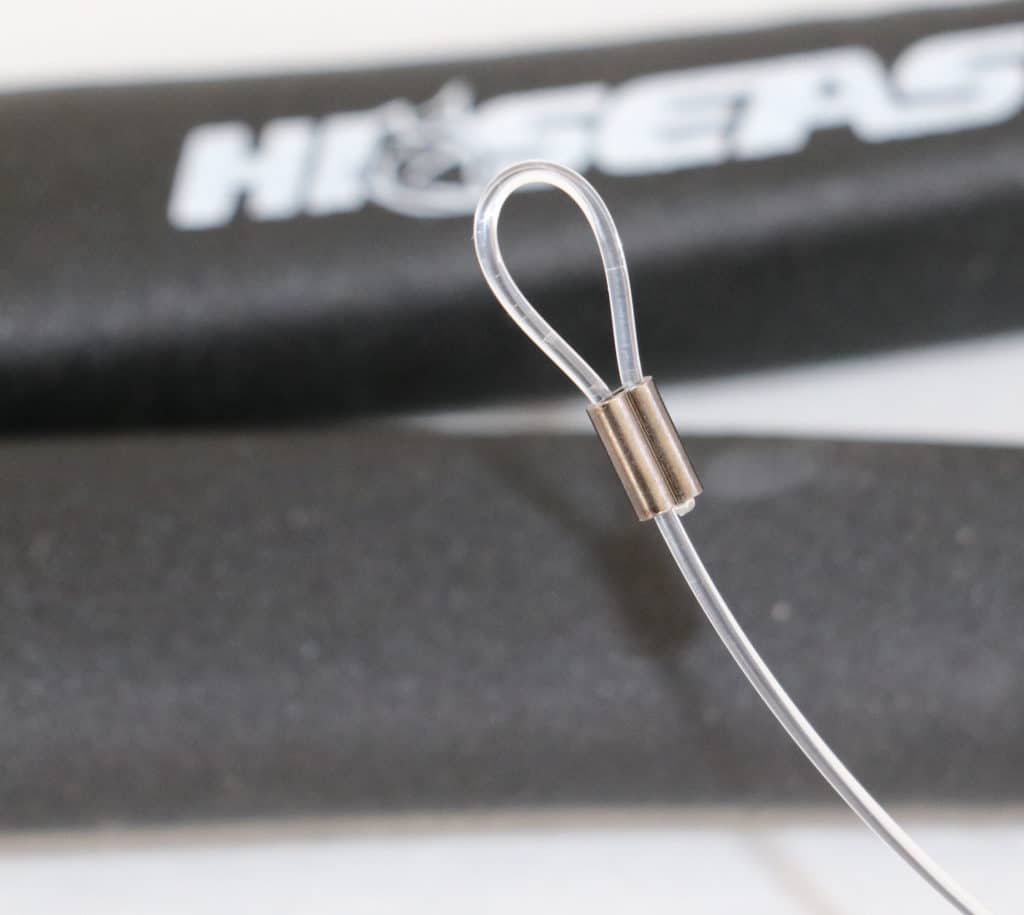

Avoid Kinking the Loop

Avoid Kinks

Jim Hendricks

This advice pertains to loops that have been crimped without using thimbles or other chafe protection. While tightening the loop, do not make it excessively small—just size it enough to avoid kinking.

Match Diameters

Matching Dies

Jim Hendricks

The jaws of crimping tools like the Hi-Seas Deluxe mini hand crimper feature multiple indentations known as dies. These facilitate crimping of various sleeve sizes. It’s important to match the size range indicated next to the die with the inside diameter (ID) of the sleeve. For copper sleeves, refer to the ID of one of the barrels, while for oval aluminum sleeves, use the shortest inside measurement.

One or Two Crimps

Crimping Location

Jim Hendricks

For longer sleeves, crimp them twice, about 2 to 4 millimeters away from both ends. With shorter sleeves and thicker crimpers, there’s often insufficient space for two crimps, so make just one in the middle. “It’s crucial to avoid crimping too close to the sleeve’s end, as this could damage or nick the leader line,” Rotello warns. “Ensure there’s enough space so that the sleeve’s end flares slightly.”

Optimal Pressure

Crimping Pressure

Jim Hendricks

Insufficient pressure while crimping may cause the line to slip out, whereas excessive pressure could harm the leader line, potentially leading to breaks. A high-quality crimping tool such as the Hi-Seas Deluxe mini hand crimper is adjusted to ensure the application of the correct pressure, enabling the creation of secure crimps without damaging the line.

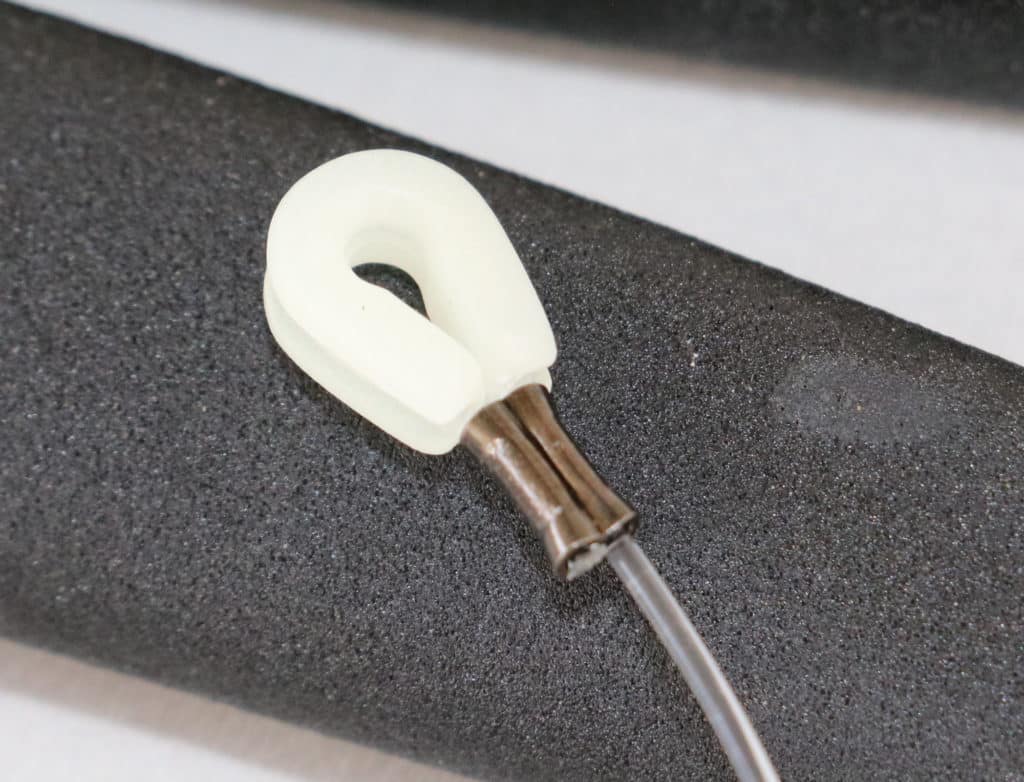

Chafe Protection

Chafe Protection

Jim Hendricks

Using chafe protection like thimbles or tubing prevents the leader loop from degrading during trolling or while fighting a fish. “I like to incorporate chafe protection when pursuing marlin,” Rotello states. “This becomes particularly crucial near the hook since a marlin’s bill and mouth can feel like 60-grit sandpaper.” As with crimp sleeves, thimbles and chafe tubing should be matched to the diameter of the leader line.