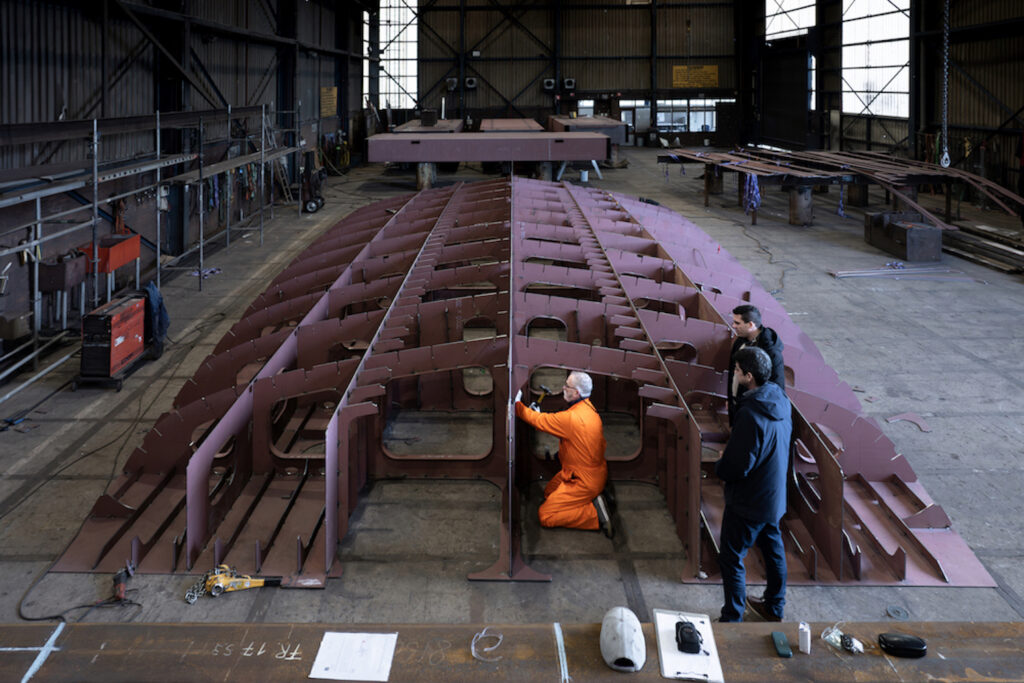

Heesen Yachts has officially marked the keel laying for Project Grace, a 50-meter Steel Fast Displacement Hull Form (FDHF) yacht. This milestone signifies the launch of Heesen’s new 50m series, which was introduced at the Monaco Yacht Show last year.

The keel laying ceremony was conducted under the supervision of Lloyd’s Register, emphasizing Heesen’s unwavering focus on quality and precision.

The keel laying was conducted with the presence of a surveyor from Lloyd’s Register. This significant milestone in yacht building represents the official commencement of a groundbreaking vessel that embodies Heesen’s commitment to exceptional yacht construction, merging advanced technology with unmatched craftsmanship.

A Collaboration Rooted in Excellence

- Steel Hull Expertise: All Heesen steel hulls are constructed off-site in collaboration with Talsma Shipyard, renowned for its exceptional steel craftsmanship in Friesland, Netherlands.

- Advanced Construction Techniques: By applying proprietary techniques, Heesen ensures efficient production timelines while maintaining the highest quality standards.

- Once the steel hull is completed, it is transported to Heesen’s Oss shipyard for engine installation, connection, and outfitting.

All Heesen steel hulls are constructed off-site to avoid any cross-contamination with its aluminum production. Heesen has established a long-standing partnership with Talsma, a highly respected shipyard in Friesland, a Dutch region famous for its maritime craftsmanship. This collaboration utilizes Talsma’s expertise in steel construction, ensuring that each hull adheres to Heesen’s rigorous quality standards. Strict quality control measures are implemented at every construction step.

Exceptional Design Meets Innovation

Heesen has partnered with Harrison Eidsgaard, a prestigious British design studio, to deliver a refined and timeless yacht design.

Key design features include:

- 50-meter length with a gross tonnage of 499 GT.

- Fast Displacement steel hull ensuring optimal comfort and excellent seaworthiness.

- Optional integration of Heesen’s hybrid solutions for efficient power management and silent cruising.

“The design captures Heesen’s DNA: sporty, fast, yet timeless and dynamic.” — Peder Eidsgaard, Designer.

Heesen applies its own construction techniques, developed over years of innovation and experience, during the building process at Talsma. These methods optimize time, ensure efficient production, and uphold excellent hull quality. Through close collaboration with Talsma, Heesen consistently enforces these techniques and quality benchmarks, resulting in sturdy, dependable steel hulls that reflect innovative design and sophisticated engineering.

Once the steel hull is completed, it will be transported through rivers and canals to Heesen’s shipyard in Oss, where the installation of the engine room, connection, and outfitting will occur, ensuring that the final product aligns with Heesen’s stringent Dutch standards of excellence.

In developing this new 50-meter Steel Series, Heesen embraced a holistic approach and collaborated with British studio Harrison Eidsgaard for the exterior and interior design. With a length of 50 meters and a gross tonnage of 499 GT, this yacht is equipped with a Fast Displacement steel hull that offers remarkable seaworthiness and optimal comfort in all sea conditions. The design also allows for the optional integration of Heesen’s hybrid solutions for intelligent power management and silent cruising, harmoniously combining luxury and sustainability.

“The design of Heesen’s 50-metre steel yacht radiates confidence,” remarks Peder Eidsgaard. “In line with the company’s DNA, it captures the sporty and fast appearance of the aluminum yachts, transforming it into a dynamic, agile shape. The profile is neither radical nor extravagant; instead, it is refined and timeless. This yacht has been designed to endure throughout the years.”

The yacht’s sleek, modern lines and low bulwarks enhance visibility, integrating the surroundings into its profile. Full-height windows and the lack of fashion plates maximize natural light, fostering a connection between the interior and exterior. The layout is designed for guest comfort as well as crew efficiency, featuring separate crew routes for discreet service and ample hidden storage for tenders and toys on the main deck forward.

“The secrets to a successful layout in a 499GT yacht are simplicity and versatility,” states Robert Drontmann, Heesen Sales Director. “We aim to maximize lifestyle space for guests while ensuring that crew have optimal working areas for delivering an exceptional experience. Features like the infinity pool or the unique coffee table on the sun deck, which also serves as an atrium skylight, will attract guests to gather. The sun deck will be spacious enough to accommodate up to 20 guests for outdoor dining. Hospitality is a core element in yachting, and we wanted to ensure that visiting day guests can be properly entertained as well.”

Peder Eidsgaard and other key members of the design and engineering teams are available for interviews to discuss the innovative design and features of Project Grace.

YN 21350, Project Grace is currently available for sale, with delivery anticipated in Q1 2027.